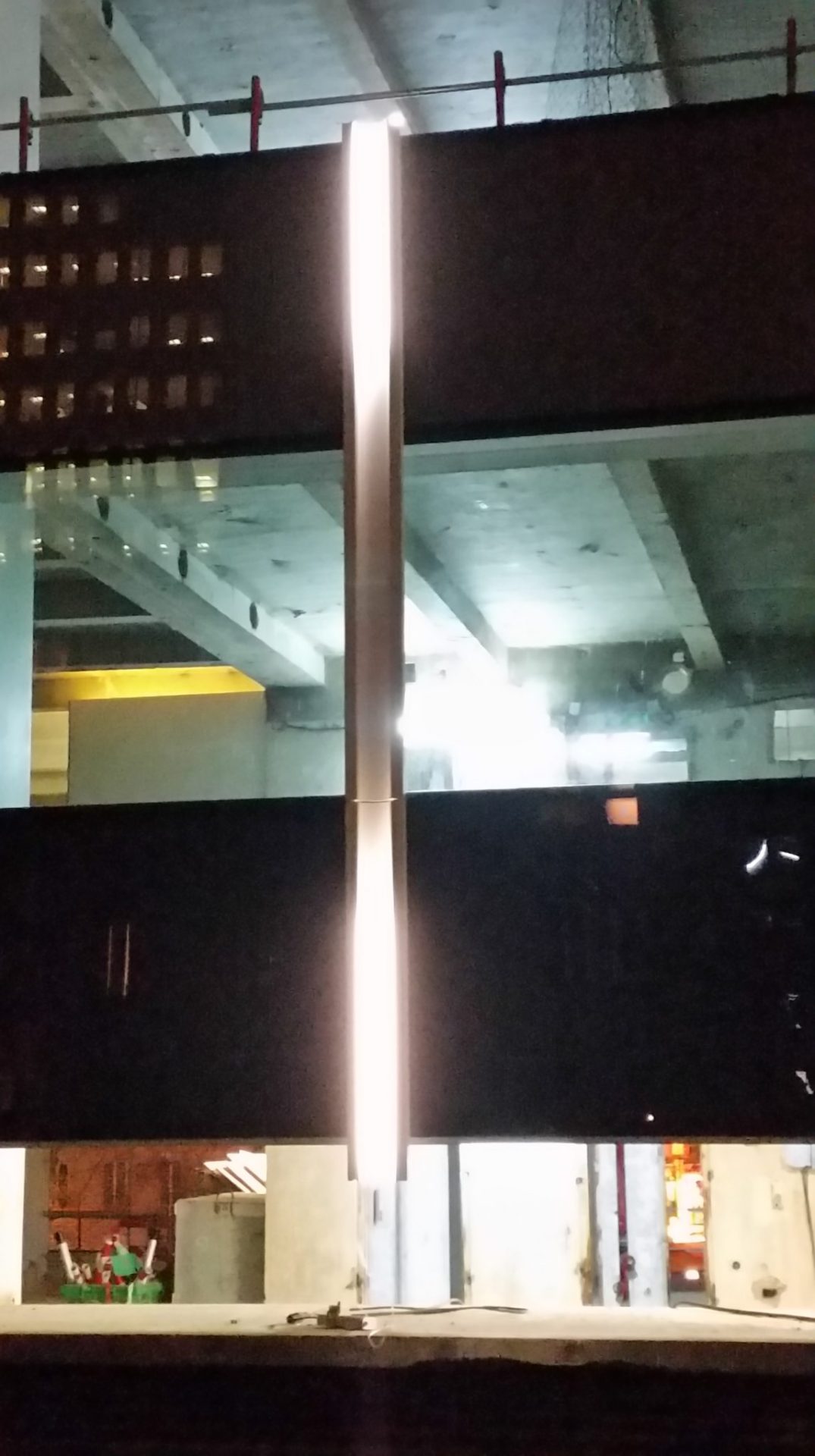

The project started with white stripes light temperature tests on site. It was an office building of which only the bare concrete structure remained. Other prototypes tested involved progressive filters of 1,2m and 2m in order to dim the light at the corner of the facades. Based on the prototypes, our partner 8:18 asked extra 40cm progressive filters where lines intersected. We obtained the desired effect by doubling the degraded filters of Glace Control (we thank them here for their commitment). The LED strips with progressive filters are first stuck inside standard aluminium profiles before being glued inside the large white rails of the facades. Henkel France helped us to choose the right glues for silicone LED strips to aluminium and aluminium to aluminium. The glues are supposed to last for twice the guarantee period.

The LED strips have been made to order : cables with male waterproof connectors, soldered and protected, bending of the cables as a pre-constraint. Most of all, we adapted the power consumption of the LED strips to follow the specification. The DMX interfaces and the controller are off the shelf. Splitters come every other floor to spread the DMX signal. Eiffage, our customer, coded the strips sections, not to mention the external lighting project coordination. We did the DMX programming including night tests with our partner 8:18.